OUR UTOPIA

We know we have a long way to go. But, based on everything we’ve researched, read and understood, we have a utopia we want to strive towards, fully aware that it will evolve as we learn more.

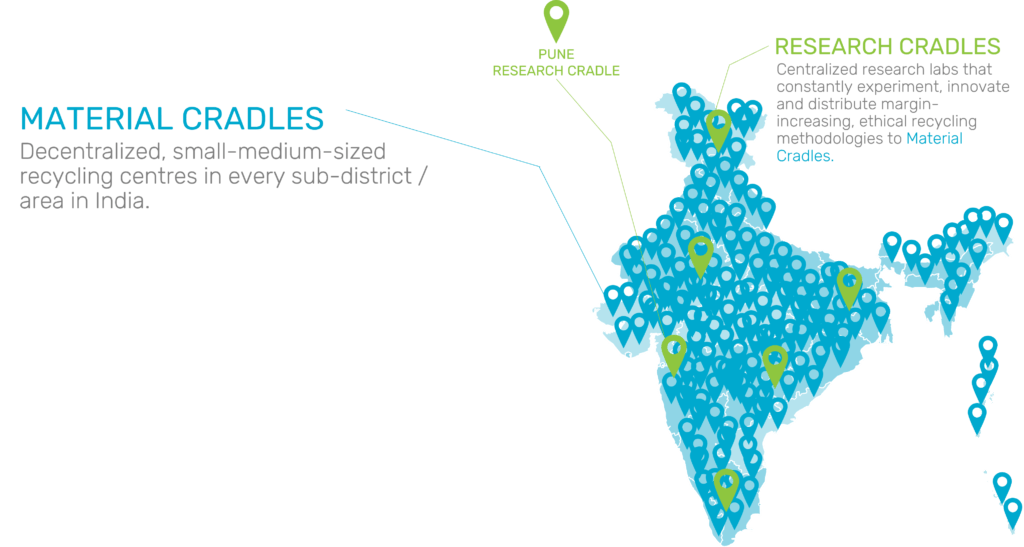

Our utopia would consist of decentralised “material cradles” or recycling centres at the sub-district level across India that upcycle all types of municipal solid waste, formalize and incorporate the informal sector, and are financially sustainable, mini-manufacturing units. These would be supported by centralised “research cradles” that would be research and development centres focused on increasing the value of waste.