Dear Friend of Ashaya,

It has been over two years since I started writing these letters to you. 28 long months that have flown by. And we are finally launching.

We are launching the world’s first recycled sunglasses made from packets of chips! And we couldn’t be more excited (and nervous).

And, we would LOVE your help.

Please help us spread the word! Please share this (short) video and our e-commerce website (yes, WITHOUT™ is our new brand). Or at least follow us on Instagram so we look a little more legitimate.

Please get your friends, your aunty, your cousin, and your son to buy a pair. And if sunglasses aren’t their thing, we are also selling some funky recycled coasters.

These will probably be the most sustainable products you’ll own, both environmentally and socially. But they are not only sustainable, they’re also highly functional.

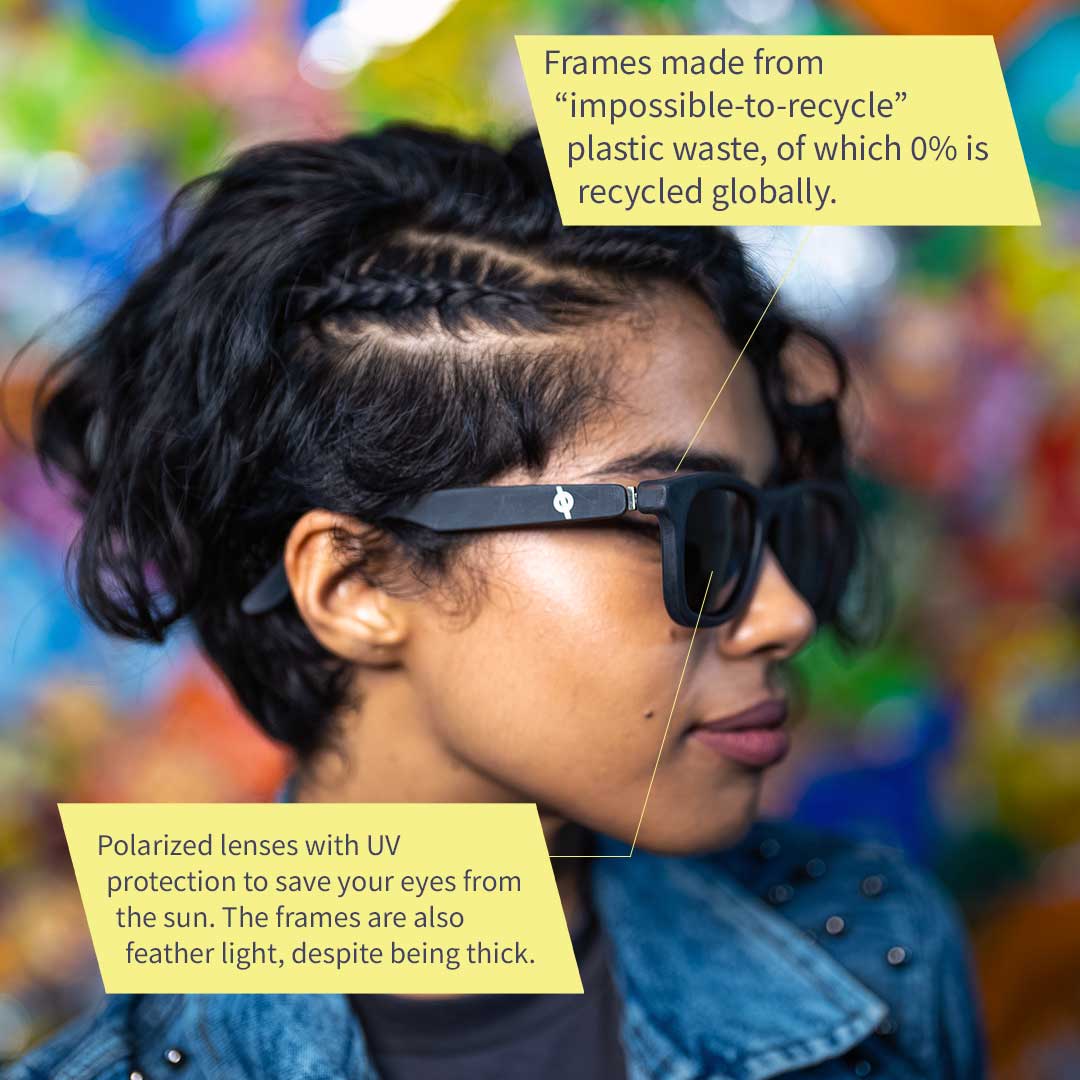

Our r-Sunglasses are super light for a thick pair of sunnies (26 grams) and durable because of the material’s flexibility. Shreyas, one of our design engineers, gets his friends to sit on them and see if they break or not. They don’t. They are nice and bendy.

The material is also silky to touch, which makes them sit comfortably on your temple. The lenses are UV polarized and dark, pretty much giving the finger to the sun, and some coolness to your eyes.

Some friends and I test-drove them in Bombay during Lollapalooza India, and we didn’t even notice they were on our head. And no, we didn’t notice the sun either. Yes, my friends and I are biased, but why don’t you try them and let me know?

These are still in beta mode so the more feedback we get, the better.

Environmentally, as you’ve heard many-a-time, we are recycling post-consumer metalized multi-layered plastic packaging (MLP) – i.e. packets of chips, chocolate wrappers, and so on – unfiltered. As in, we don’t pick and choose what MLP to recycle – we recycle all of it.

0% of this is recycled globally – it literally rounds down to 0. It’s considered “impossible” to recycle because of how many different materials it has, and how inconsistent it is. 80% of all leakage into the oceans is flexible packaging, not straws.

But we’ve found a way. A way to extract materials from it and upcycle them into high quality, largely consistent materials and products that are way more recyclable than the original packet of chips.

Socially, we are doing so much that it almost seems like we are making it up. I promise you we are not.

10% of our sales will go towards keeping children of waste pickers in schools. We buy waste directly from waste-pickers and pay then a premium for it. And most importantly, we formally incorporate waste-pickers into our supply chain.

We have hired 4 waste-pickers so far on a part-time basis who’s monthly income has increased an average of 120% (well, one of them had been unemployed for over 6 months so that’s more like infinity %).

We are only selling in India for now (shipping logistics to countries abroad is insane or expensive), but if you want to be our reseller abroad, give us a shout, and let’s make it happen?

Okay wow, yea a lot of selling, apologies.

But we’ve worked so hard on doing this, what else to do?

I think there lies the truth.

So far, we have only gotten love and support from friends and family, and even some unknown well-wishers, but the market doesn’t lie. Not many can deny us the story, but will they buy?

The next few months are going to be pivotal for us as we figure out the viability of our business model. Because, guess what? This is not about selling sunglasses – that’s just the start.

This is about monetizing impossible-to-recycle waste in a way that can drive our impact and sustain our operations.

Sunglasses is just a proof of concept for the potential applications of our material – which is of high-quality and comes from waste that nobody recycles.

Almost any recycled material can be used for bricks, but what about more intricate, finesse-centred applications? That’s what we want to get at.

So, Anish, why are you diving head-first into the deadly pit of B2C products? And not doing B2B instead?

Great question, and you’re not the first to ask.

We are still tiny. We do all this in two small labs that add up to 1,200 square feet in space. So, currently, we cannot do large volumes. No one really wants to buy 10 kgs of material, they want 10 tons. At our current rate of production, that would take us about 10 years.

Why not outsource then? Our patent-pending processes can’t just be outsourced. And contract manufacturers for sunglasses give us a funny look when we tell them that we want them to use our material not theirs. They hang up when we tell them the quantity we want to order for starters.

So right now, we have complete vertical integration – right from shredding the waste to cutting the lenses of our sunglasses and to finally selling them through our website.

This has proved to have way more benefits than we had imagined.

We have minimized dependencies on external stakeholders allowing us to trot along whatever happens – rent and salaries don’t wait for big corporates.

We never thought our material could feel this good after post-processing until we went to product – I can’t wait for you to feel our material, let alone wear our shades.

We have even tried tweaking our material to improve the applicability in moulding applications.

While selling, we can tell stories that no one else can because we know exactly where the waste is coming from and how it’s being recycled, and by whom.

And the gross margins are pretty healthy as well.

But Anish, this is so hard. Yea it is, but we are not doing any of this because it’s easy. This is the bet we are making.

This also doesn’t mean that we won’t do B2B in the future. Or B2G. Or B2B2C. Or B2G2B2C. We will always adapt. We will use any channel that allows us monetize waste in a way that sustains our impact and our operations. That’s the goal.

Next step: raise funds to take our technology from a micro-pilot plant to an actual pilot plant to prove out the viability of what we are trying to achieve.

So yea, that’s where we are at.

I am aware that I could be completely off about all this, and that I could have lost it a little. We’ll find out soon enough.

Glad you made it this far. My sister had warned me to KEEP IT SHORT, and I negotiated to get the salesy stuff out of the way earlier, and leave the real meat for later.

And there were so many other things that happened in the past three months – we started the process for our second patent, we hired two more waste-pickers, we won a couple of things and we got a water recycling plant installed that recycles all the water we use making our MLP recycling process even greener.

There were some lows as well, but that’s for another time.

Thank you for all your support.

Fingers crossed,

Anish